Supply Chain Solutions

Securing the links that matter for a safer nation

Fact Sheet

Shock Modeling and Supply Chain Security

Supply chains are at the heart of many of today’s national security and critical infrastructure challenges. Securing our nation’s supply chains requires a focus on information and communications technology, while also maintaining vigilance on our physical and logistical supply chains.

Over time, stakeholders have developed tools and disciplines to manage supply chain risks. These resources need continual improvement in the evolving landscape to meet sponsor needs.

For 60+ years, MITRE has been at the forefront of this challenge, enabling sponsors to secure critical supply chains and leading in the development and delivery of world-class tools, expertise, and information in support of nationwide needs. This platform exists on the intellectual and technical foundation needed to inform tangible supply chain recommendations for sponsors and expands opportunities for MITRE thought leadership in an area critical to our nation’s prosperity and security.

Understanding and Managing Risks to Mission-Critical Supplies

The modern supply chain is intricate and interconnected, spanning multiple industries and geographic regions. While this interconnectedness brings efficiency and cost savings, it also introduces vulnerabilities to shocks and disruptions. Understanding and managing risks to our nation’s mission-critical supplies is paramount to resilience and functionality.

Food, medicine, technology, everyday staples and capabilities we take for granted. Our health, our connections and our economy all rely on a robust and resilient global supply chain.

From our technology systems and equipment to our vehicles and power grids, America's most critical functions depend on partners across the globe, but supply chains are complex and vulnerable to natural and manmade disruptions.

In a rapidly changing economic and geopolitical landscape, MITRE understands that securing our supply chains requires a whole of nation approach.

It demands a collaborative effort, transcending industry and government. From risk assessment and strategic planning to technology integration and policy development, MITRE takes a multidisciplinary approach.

Our diverse teams develop and apply leading edge strategies to detect and mitigate the universe of supply chain risks.

We transform data into actionable insights, enabling our nation's decision makers with a 360 degree view of the supply chain.

At MITRE, we're not just thinking about today's challenges, we're developing tools and strategies to secure the supply chain of the future.

At MITRE, we work with industry, government and academia to bring together all aspects in understanding of supply chains.

MITRE is building upon the data-driven tools we use for firm level supply chain optimization and adding a myriad of other disciplines, such as strategy development, risk management, scenario and resiliency modeling.

For example, my team built a model to help our sponsor understand the economic consequences of supply chain disruptions in global maritime shipping.

I'm a data scientist. I help create the commodity risk dashboard to help identify dependencies in supply chains.

In my role as the outcome lead for lithium ion battery technologies and supply chain, I shape work to inform strategic defense investments and acquisition policy that impacts hundreds of different military systems.

Resilience supply chains are essential for the continuity of our critical infrastructures, and the integrity of the supplies delivered and used is essential to our national critical functions.

Together, we can build a more secure and resilient supply chain.

Contact us to learn how you can work with us at supplychainsecurity@mitre.org.

Key Capabilities

Building SCRM into Agencies’ and Organizations’ Acquisitions

With complex networks spanning continents and involving numerous suppliers, manufacturers, and distributors, ensuring the integrity of the supply chain is critical. Risk to supply chains is generally assessed from a shock standpoint, but it is just as important to apply rigorous risk assessment to the acquisitions process. When it comes to acquisitions, it is vital to understand the access vendors have to different supplies and the identity of the suppliers.

MITRE can assist agencies with acquisitions planning and strategy. We help answer questions like:

- What are the issues that sponsors should be aware of when involved in acquisitions related to supply chain?

- What are the measures they should have in place for managing risk within their acquisitions strategy?

- What clauses within the Federal Acquisition Regulation (FAR) help protect the government when it comes to cyber supply chain risk?

- What aspects of the supply chain require continuous monitoring and how can a federal agency pivot in the face of changing events?

By conducting thorough assessments across all stages of the supply chain—from procurement and production to distribution and delivery—MITRE helps organizations proactively identify potential risks, such as counterfeit components, transportation bottlenecks, or cyber threats.

Cyber Supply Chain Risk Management

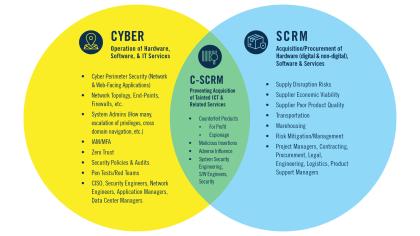

As a subset of supply chain risk management (SCRM), the following is an overview of the activities that focus on managing exposure to risks associated with leveraging the supply chain as a cyber attack vector:

1. What is C-SCRM?

Cyber supply chain risk management (C-SCRM) is a subset of SCRM that specifically focuses on managing exposure to risks associated with the acquisition/procurement of potentially tainted (hygiene-related, counterfeit, malicious) digital products (e.g., hardware, firmware, semiconductor chips, software) and/or technology services that could enable an adversary to negatively impact U.S. government sponsors’ operations and missions.

2. Comparing and Contrasting SCRM, C-SCRM, and Cybersecurity Domains

The terms “supply chain risk management,” “cyber supply chain risk management,” and “cybersecurity” are often intermingled or conflated. The diagram below explains how these three disciplines differ in focus and scope and who the key actors/stakeholders are for the respective domains.

Shock Modeling Capability

With a more advanced view of our nation’s BEG through CRD, it’s also essential to consider the instability of our global environment and the potential impacts. How can we understand the various impacts of events affecting our supply chain?

In order to enhance the resilience of our supply chain, MITRE created the Shock Modeling Capability to support systematic analysis and simulation of scenarios that help the sponsor anticipate and prepare for potential disruptions. By leveraging advanced data analytics, machine learning algorithms, and simulation techniques, sponsors can assess the vulnerability to our supply chains and impacts over time to the American economy, including specific industries that may be hit the hardest.

Sustainability and Circularity

MITRE leverages new technologies and processes to decrease reliance on foreign sources for critical minerals and minimize waste. The disposal of products at the end of their life poses complex challenges related to methods and environmental impacts. Many of these products contain critical minerals that can be reused, potentially reducing hazardous mining and foreign dependency. The solution lies in building circular economies to eliminate waste and maximize reuse.

At MITRE, we use advanced models to simulate policy impacts, providing incentives for more circular processes. We integrate these models with technical expertise in manufacturing and materials to enhance product recyclability and incorporate recycled materials effectively. This allows us to comprehensively model the complex systems needed for circular economies.

Ultimately, MITRE’s approach enhances supply chain resilience and sustainability while reducing reliance on foreign sources with poor environmental and labor practices.

High-Fidelity Custom Deep Dive Analysis

Certain products or components may require a more comprehensive analysis to understand their dependencies and vulnerabilities. MITRE can provide a custom deep-dive analysis that enables sponsors to delve into the intricacies of potential risks and impact of disruptions. With this information, sponsors are better positioned to devise targeted strategies that enhance resilience.

Tools

Commodity Risk Dashboard

From mass lockdowns to disruptions in transportation and production, the COVID-19 pandemic exposed the fragility of the global supply chain. In response, President Joe Biden issued Executive Order 14017 (c. 2021) to strengthen U.S. supply chain resilience. But which goods, from a geopolitical standpoint, have an increased risk of disruption?

In response, MITRE created the Commodity Risk Dashboard (CRD). The CRD distills six months of custom analysis into a five-second rapid landscape view of the current state of a supply, including a basket of essential goods (BEG). The CRD also provides a lightweight relative-risk ranking across a sponsor’s group of priority goods, rapidly informing sponsors where additional focus may be needed.

The CRD provides a flexible screening capability that can rapidly identify dependencies for specific goods, helping focus future deep-dive efforts. The dashboard uses free and open data (i.e., U.S.A. Trade Data) so that it can be broadly shared and accessed across MITRE and its sponsors. Among other features, the dashboard computes a risk indicator for each commodity based on the geopolitical risk associated with the countries exporting those goods to the United States.

Access to the CRD is available to sponsors through special request.

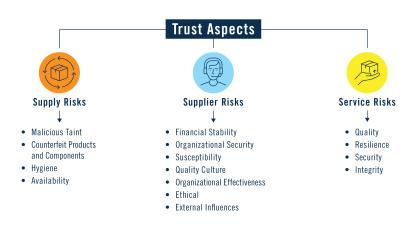

System of Trust: Comprehensive SCRM Methods for Agencies and Organizations

Today’s increased focus on the need for robust and resilient supply chains, trustworthy partners, and trusted components and systems that are globally manufactured, demands a reliable process for understanding risks that can impact trustworthiness. This path must be broadly understood, shared, and usable at scale.

As a method for addressing these supply chain security challenges, MITRE developed and introduced the System of Trust™ (SoT) Framework. This framework is designed to identify and address the specific concerns and risks that prevent organizations from trusting suppliers, supplies, and service providers.

Most importantly, the framework offers a comprehensive, consistent, and repeatable methodology—for evaluating suppliers, supplies, and service providers alike—that is based on our decades of supply chain experience, deep insights into the complex challenges facing the procurement community of interest, and a broad knowledge of the relevant shared thinking on this topic in literature and standards.

Joining the System of Trust Community

The System of Trust (SoT) Community provides a collaboration platform where industry, government, academia, and MITRE can evolve and refine the body of knowledge of potential risks from a supply chain. The live repository of SoT knowledge is in the prototype Risk Model Manager (RMM) cloud-native application that allows MITRE to add, delete, and otherwise revise the corpus of potential risks from a supply chain. Among other features, the body of knowledge in RMM includes listings of potential sources of the data to evaluate whether a particular risk aspect can be viewed either from a data source or through some measurement activity.

Access to a publicly available version of RMM and the SoT body of knowledge is available to all through a registration request form to receive MITRE Partner Network (MPN) and RMM logins.

Contact us at supplychainsecurity@mitre.org to learn more.

Black Pearl Supply Chain Analysis

MITRE characterizes global trade data to develop and evaluate analytic approaches to generate investigative leads for illegal activity involving international trade. MITRE analyzes trade networks and possible sanctions obfuscation that use subsidiaries to enable illegal trade activities.

AI FORGE: Artificial Intelligence Framework for Optimizing Resilience and Gaining Efficiencies

Supply chain risk and resilience professionals require faster data analytics to effectively interpret vast and growing datasets. To address this need, MITRE developed the Artificial Intelligence Framework for Optimizing Resilience and Gaining Efficiencies (AI FORGE). This framework establishes a consistent methodology for enhancing productivity, providing rapid baseline insights, and uncovering vulnerabilities and risk scenarios in supply chains. By collaborating with government and industry partners, AI FORGE aims to improve resilience outcomes nationwide.

Key elements of AI FORGE include advanced prompt engineering for optimizing AI interactions, integrating supply chain expertise for accuracy, and creating an innovative user interface to streamline workflows. The framework offers immediate productivity gains for analysts, enhances vulnerability identification, and supports long-term strategic planning for supply chain resilience. Overall, AI FORGE presents a data-driven solution that addresses workforce challenges while improving national resilience through enhanced analytical capabilities.

SCKPI: Supply Chain Key Performance Indicator

The MITRE Supply Chain Key Performance Indicator (SCKPI™, pronounced Skippy) tool empowers stakeholders to identify relevant indicators for supply chain resilience risks and align strategic goals with objective performance measures. Unlike traditional key performance indicators that focus primarily on profit, SCKPI organizes metrics to evaluate critical supply chain resilience at a national level, fostering a holistic approach to resilience rather than profit-seeking.

Developed with input from MITRE supply chain experts, SCKPI serves as an interactive Tableau Dashboard that helps decision-makers find the most pertinent KPIs for their objectives. Users can explore KPIs by risk type, supply chain phase, and timeframe through an intuitive interface. The dashboard provides concise definitions and related categories, allowing for filtering by parameters such as “Logistics” risks and “Deliver” phases, ultimately enhancing understanding and supporting informed decision-making in supply chain resilience strategies.

Strategy

Strategic and Geopolitical Competition

The challenge of strategic competition in supply chain resilience is increasingly critical in today’s globalized economy. As nations and corporations vie for economic dominance, supply chains become battlegrounds for geopolitical influence and technological superiority. This competition can lead to disruptions, as countries impose trade barriers or prioritize domestic production to safeguard national interests.

Additionally, the reliance on a few key suppliers or regions for essential components makes supply chains vulnerable to external shocks, such as political tensions or natural disasters. Companies must therefore innovate and diversify their supply networks, investing in technology and fostering partnerships to enhance adaptability and mitigate risks. Balancing efficiency with resilience becomes a strategic imperative, requiring a nuanced understanding of global dynamics and proactive risk management.

MITRE leverages a unique system of systems (SoS) approach to understanding supply chain risks and vulnerabilities to better understand the impact of nation-state competition on U.S. supply chain resiliency. Taking a multi-disciplinary approach that includes MITRE experts in International Strategy & Geopolitics, Supply Chain Management, Data Science, Trade & Economics, and Technology, MITRE dives deep into supply chain vulnerabilities to proactively identify and characterize supply chain risks and their optimal mitigation strategies.

Strategy and Design

The complexity of supply chains poses significant strategic and policy challenges due to their intricate and ever-changing nature. While predicting the future with certainty is impossible, gaming and foresight provide a structured framework for understanding potential futures. By embracing uncertainty and focusing on insight rather than prediction, these methods improve our ability to address the dynamic nature of supply chains and respond to emerging challenges.

MITRE’s capabilities in gaming and strategic foresight offer valuable tools to navigate supply chain uncertainty. Sometimes misunderstood as speculative, MITRE’s methods are grounded in rigorous, data-driven approaches and are a key part of our multi-disciplinary approach to supply chain management. Gaming and strategic foresight allow stakeholder experimentation in low-risk settings, simulating real-world outcomes and fostering flexible thinking. The approach helps explore potential futures, identify unforeseen variables, and enhance adaptability. A key benefit is the generation of qualitative and quantitative data, which can be analyzed through interdisciplinary models and expert insights.

IR&D Supply Chain Efforts (Sustainable Social Services)

Supply Chain Shock Model

Recent events have highlighted the vulnerability of the U.S. supply chain to geopolitical and transportation disruptions. To help policymakers understand the economic impact of such shocks and interventions, MITRE developed the Supply Chain Shock Model. This framework models the interdependencies within the domestic supply chain, capturing how labor issues, trade restrictions, and transportation delays affect economic productivity. It supports various productivity and disruption metrics, allowing analysis of specific industries to identify regions most impacted by shocks and those benefiting from interventions.

Case Studies: MITRE’s SCRM team has analyzed scenarios affecting the U.S. economy, including:

- Trade restrictions with China and Southeast Asia

- Import delays from port disruptions, like the Francis Scott Key bridge collapse, impacting Maryland’s economy

- Natural disasters, such as hurricanes, affecting transportation, labor, and demand in key sectors like energy

- Increased scarcity of key inputs due to environmental changes

The model uses input-output analysis to quantify industry dependencies across the economy, considering inventory sizes, productive capital, and labor. It simulates how input scarcity leads to prolonged disruptions and models recovery paths when shocks subside.

Pharma Supply Chain

MITRE conducted initial research to design and develop a graph store that maps the complex network of suppliers for key starting materials (KSMs), active pharmaceutical ingredients (APIs), and drug manufacturing capabilities. This tool aims to uncover dependencies in adversarial nations. Currently, MITRE is advancing this research by testing advanced machine learning techniques to identify vulnerabilities in the pharmaceutical supply chain for critical medications. The approach also explores mitigation strategies, such as alternative suppliers, manufacturers, and substitutable medications.

Supply Chain Retrieval-Augmented Generation (RAG)

The newly launched IR&D research project aims to develop and test techniques for generating up-to-date supply chain information for modeling and analysis. Current approaches often rely on outdated trade, production, and consumption data, overlooking critical material shortages and geopolitical impacts. This research is working towards an automated, large-language model (LLM)-based prototype to enable real-time supply chain analysis by continuously acquiring, transforming, and ingesting information. By reducing the latency in updating the augmented LLM, more timely analysis of supply chain risks can be achieved.

Circular Economies for Recovery and Reuse

In collaboration with the National Institute of Standards and Technology (NIST), MITRE is developing a model for circular supply chains involving lithium iron phosphate (LFP) batteries. The project explores how LFP batteries can be designed for recovery, reused in secondary applications, and recycled at the end of their lifecycle, allowing materials to re-enter battery production or other industries. The primary goal is to establish a domestic circular economic model for LFP batteries, utilizing publicly available, commercial, and non-traditional data. This enhanced model will inform recycling standards and government incentives, simulating stakeholder responses to policy changes aligned with the Federal Consortium for Advanced Batteries. Future iterations aim to extend this approach to other critical materials.

COVID-19 Healthcare Coalition

During the COVID-19 pandemic, supply chains, particularly those for medical supplies, faced significant disruption due to business suspensions, reduced freight capacity, and rapidly shifting demand patterns. In response, MITRE played a key role in forming the COVID-19 Healthcare Coalition, a group of approximately 1,000 private sector companies dedicated to addressing the pandemic’s challenges. Tackling supply chain issues was a central focus of the Coalition.

Through this effort, Coalition members successfully delivered 675,000 masks to over 60 locations, accelerated the production of 10,000 affordable ventilators, and created a marketplace catalog to connect buyers with available resources. MITRE also led the development of predictive forecasting models, enabling organizations to proactively assess personal protective equipment (PPE) needs and optimize resource use.

MITRE’s involvement in the COVID-19 Healthcare Coalition underscores our commitment to collaborating with government and industry to build effective, comprehensive national supply chains that address the needs of the American people and support national and economic security.

Switching Costs and Supply Chain

Growing geopolitical tensions between the U.S. and China have heightened concerns about supply chain resiliency, prompting a need to diversify supply chain relationships with other nations. The COVID-19 pandemic only intensified these concerns regarding supply chain resiliency, leading to Executive Order 14017, which initiated a review of supply chains for critical products like semiconductors and pharmaceuticals. In light of this ever-evolving landscape, MITRE’s Center for Strategic Competition conducted research to quantify supply chain risks and assess the costs of decoupling shocks, aiming to identify U.S. sourcing of critical products and evaluate how proactive de-risking policies can alleviate economic impacts.

MITRE’s research identified key facts about U.S. sourcing behaviors, emphasizing China’s role as a crucial supplier and highlighting underutilized countries as potential suppliers. A model was developed to explore the repercussions of reduced Chinese imports and estimate the impact of policy shifts promoting supply chain de-risking. The model was applied to scenarios of unexpected decoupling and proactive de-risking, showing that a trade agreement with Indo-Pacific Economic Framework (IPEF) partners could reduce economic costs for U.S. importers. This analysis suggests that reducing tariffs through such agreements could benefit sectors like critical minerals and semiconductors, mitigating the risks associated with decoupling from China.